Beyond the assessment: improving the future

Asset management planning and catalyst lifetime extension have two key objectives: first, to identify non-catalyst improvement potential, which could lead to the extension of catalyst lifetime without touching the catalyst, and second, to realistically forecast and quantify remaining catalyst lifetime in excess of the OEM guarantee, to achieve significant cost savings. Once improvement measures have been identified, ENGIE Laborelec can also assist with their implementation, including issuing any required guarantees.

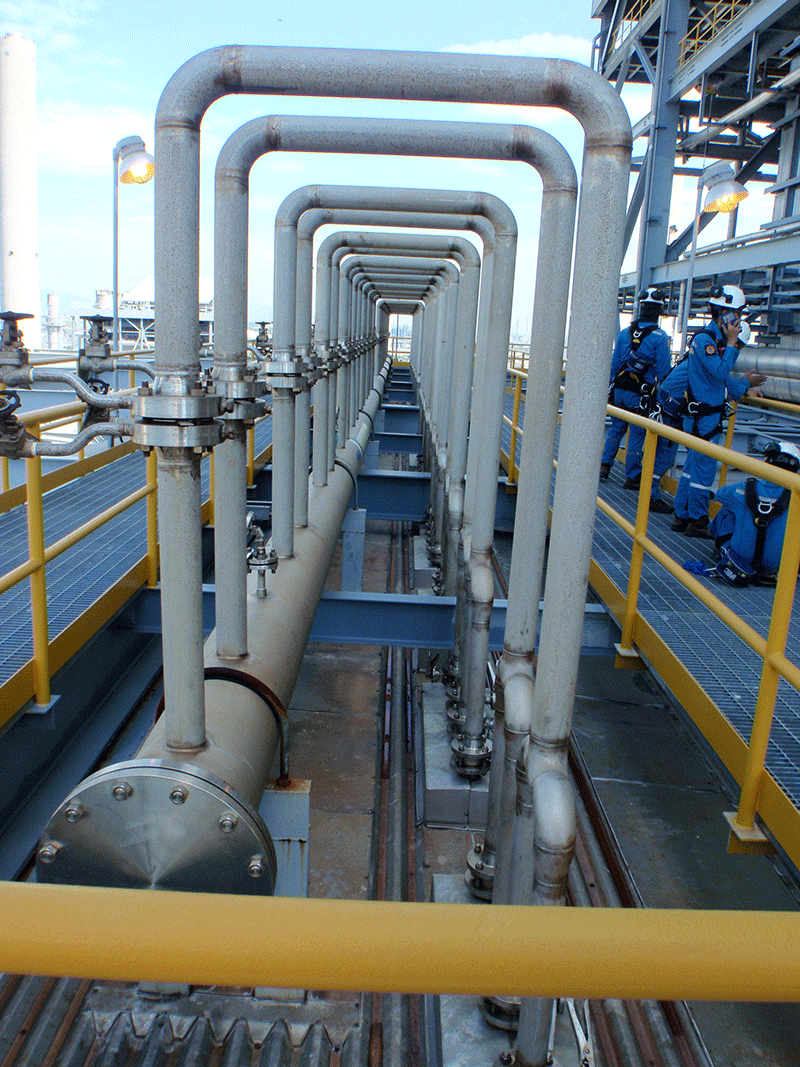

AIG tuning solution

Tuning the ammonia injection grid (AIG) is essential for long catalyst lifetime. Indeed, when ammonia is not injected according to the NOx distribution profile, different areas of the catalyst show either an excess or shortfall of ammonia compared to NOx. The consequence is a combination of higher NH3 slip and/or higher NOx, leading to extra costs, despite the potential for the catalyst to continue to control both NH3 and NOx emissions.

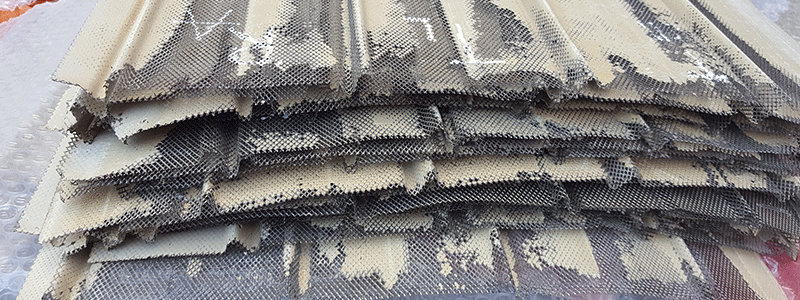

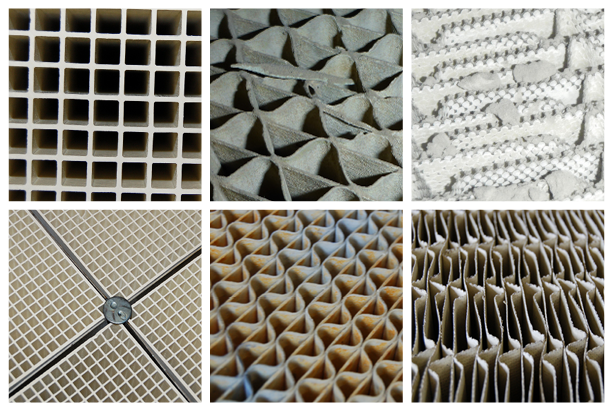

SCR deNOx cleaning upgrade solution

Catalyst plugging is a typical issue for SCR technology. It leads to:

-

- higher power costs due to extra pressure drop

-

- higher catalyst costs due to reduced availability of catalyst pores

-

- higher outage costs due to increased outage frequency

-

- higher ammonia costs due to reduced catalyst performance

We have the experience to identify the root cause of catalyst plugging and to offer a clear solution which can combine SCR flow modelling, catalyst redesign, enhanced O&M of current cleaning systems and upgrading cleaning systems. Unlike OEMs and specific equipment vendors, our custom solution is based on the lowest possible total cost of ownership. Our approach has been successfully used in diverse applications (coal, waste, glass, oil, etc.) and implemented in more than 20 different reactors.

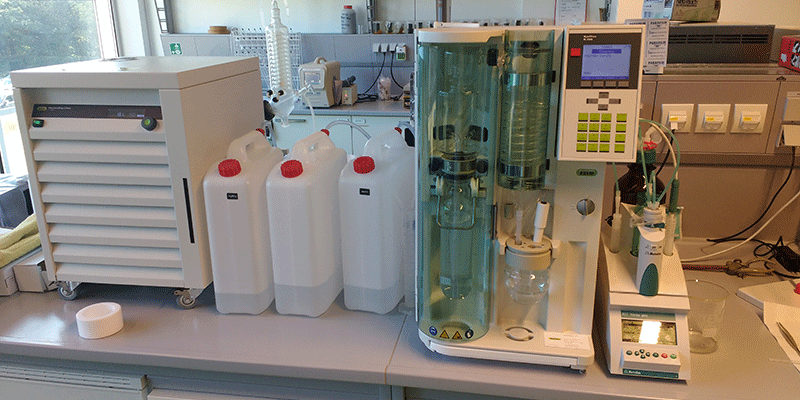

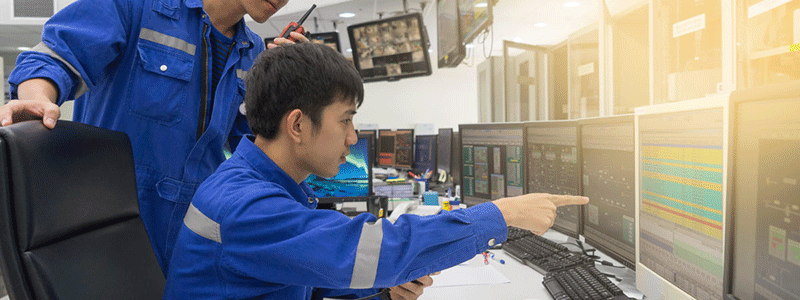

NH3 control and monitoring solutions

State-of-the-art NH3 injection control logic is important in keeping NH3 costs to the minimum while achieving the required NOx emission levels. In addition, NH3 slip monitoring is an effective way to detect non-catalyst related issues when combined with catalyst testing results. ENGIE Laborelec can put its experience at your service to implement or improve these two aspects, based on our SCR expertise and extensive knowledge in the areas of I&C, emission measurement and chemical analysis. Other less common tests are also available. Feel free to get in touch with us if you have specific needs.

SCR flow distribution solutions

Optimum distribution of flow, ash and NOx emissions is key for high performance SCR. Suboptimal design can lead to increased NH3, erosion and plugging costs. Laborelec is your ideal independent partner to help you find the root cause of distribution issues and to propose clear custom solutions. Our complete confidence arises from our long experience in this field and our particular expertise in flow modelling and Computational Fluid Dynamics (CFD).

Catalyst solutions

Our prime focus is to postpone as far as possible the costly replacement of SCR catalysts. Nevertheless, sooner or later, some action in relation to the catalyst will be required. Depending on specific plant conditions, a choice will have to be made between the two following options:

- Catalyst regeneration

- Purchasing of new catalyst

In some situations, catalyst regeneration can be a cost-effective solution, although this option must be considered carefully, taking feasibility, quality and performance criteria fully into account. Where it is feasible, and the risks are acceptable, catalyst regeneration can be the best option to achieve the lowest possible total cost of SCR ownership.

In other situations, catalyst regeneration is either not feasible or not compatible with the expected quality or risk profile of the SCR plant. In such cases, the option of purchasing a new catalyst is then the single alternative. ENGIE Laborelec provides support to identify the most suitable catalyst and associated products, each with their own strengths and weaknesses depending on the application and specific SCR challenges.

ENGIE Laborelec, is an independent player, and therefore not biased in favour of any particular new catalyst or regeneration system, as typically the case with catalyst manufacturers or regeneration companies. With our 20 years’ experience in the field, and specific knowledge of your SCR asset, we can integrate the best solution for your expectations, focusing on the lowest possible total cost of ownership.

ENGIE Laborelec provides support to identify the most suitable catalyst, each with their own strengths and weaknesses depending on the application and the specific features of your deNOx installation.